|

Why was 11th June, 2024 an important date?! Because on that day, there were only 2030 days left until 1 January, 2030?! And why does that matter, you might well ask?!

Well, 2030 is the year in which we are due to have achieved all of the #SDGs, or UN Sustainable Development Goals. These are the 17 big targets agreed by all UN members back in 2015, created with the aim of achieving "peace and prosperity for people and the planet - while tackling climate change and working to preserve oceans and forests”. It is clear that each and every one of those SDGs is a “Big Ask”! The argument in favour of having BHAG’s is that they better mobilise and motivate everyone “to reach for the sky”, and in that way we will ultimately achieve more than if we had set more limited “reasonable” goals. Pinovo marked 11th June, 2024, and the remaining 2030 days left until 2030, by participating at the seminar #Wakeup2030 hosted by Inventas that shone a light on the solutions, like Pinovo's that have been developed to help us achieve the SDG’s. Pinovo is focused on and driven by SDG14 - Life below water - which aims to protect and ensure the sustainable use of oceans. We have developed and patented Clean Blasting Technology that Stops Paint Microplastic Emissions. In that way, we are playing our part to Protect Ocean Health, because….#PaintIsPlastic! The seminar was a great opportunity to remind ourselves why the SDG’s really matter, why we should be positive and optimistic about our capacity to have an impact on them, and why we must keep our eye on the prize of achieving the SDG's. Follow this link to watch the Inventas video - https://www.linkedin.com/posts/inventas_wakeup-2030-det-er-fortsatt-tid-til-%C3%A5-handle-activity-7208767848943394817-syiV?utm_source=share&utm_medium=member_desktop

0 Comments

Introducing you to the "Godfather of Microplastics", Professor RICHARD THOMPSON OBE FRS, who first used the term "Microplastic" in the journal Science 20 years ago this year, and who is a scientific lodestar for Pinovo.

Richard's important work and impact in this field has been justly recognised by his inclusion in the TIME 100 Health - follow this link to access the article - https://time.com/6968344/richard-thompson/. And that important work goes on! Richard is now a key player in the ongoing negotiations of the UN Global Plastics Treaty. He is part of the Steering Committee and Coordinator Team of the Scientists' Coalition for an Effective Plastics Treaty - a network of independent scientific and technical experts who provide scientific knowledge to those involved in the negotiations. Follow this link - https://lnkd.in/eTghSggj - to read about an interesting conversation with Richard explaining his journey over the last 20 years, and why his research on Microplastics matters to all of us. We know that Paint is the biggest source of those Microplastic Emissions to the Environment, according to the EU Commission, The Pew Charitable Trusts and EA - Earth Action, because #PaintIsPlastic. We at Pinovo, with our in-house developed and patented Clean Blasting Technology, play our part in stopping those Paint Microplastic Emissions to Protect Ocean Health. Congratulations 🙌 to our Robotics 🤖 Partner, Remotion AS for the great profile which they were given on NRK, Norwegian National Television 📺!

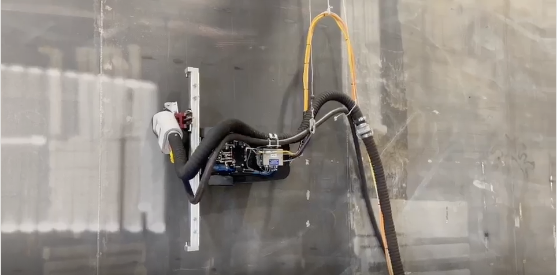

Robotic Surface Treatment Solutions marry productivity, operator safety and sustainability advantages. They deliver cleaner, safer, and more cost efficient solutions for customers. And they stop Paint Microplastics to protect Ocean Health! What's not to like about all of that?! Remotion AS We had the incredible opportunity to welcome NRK to our office yesterday, where we shared the remarkable growth story of Remotion and showcased our groundbreaking robot technology. 🤖✨ The energy in the oil industry is at an all-time high, and the interest in our innovations is booming! It's truly inspiring to see how our solutions are making waves and attracting attention from key players in the field. Stay tuned for more updates as we continue to push the boundaries and drive innovation forward! https://lnkd.in/g8aDXt4p https://tv.nrk.no/se?v=NNFA19060324 UN World Oceans Day is officially 8th June, but is marked this year by a big UN event on Friday 7th June. The powerful 💪 short video below👇 shows just why the Ocean 🌊 matters to all of us, and how you can register for the virtual event.

At Pinovo we play our part in Protecting Ocean Health by Stopping Paint Microplastics with our Clean Blasting Technology, because, as you know,.....#PaintIsPlastic! https://youtu.be/CdPQLsq9biU?feature=shared Pinovo is super proud to be one of the case studies in the GPAP/KPMG report on how the Global Plastics Treaty can help scale solutions that tackle Plastic Pollution - see page 28 in the report at this link - https://www.weforum.org/.../circular-industry-solutions.../

This insightful report highlights that policy interventions, and suitable financing mechanisms, are the two most significant factors necessary to facilitate scaling impact solutions from "niche alternatives", to becoming "mainstream" and an industry standard. That is what is happening in the world of surface maintenance, where Clean Technologies, like Pinovo's, are becoming the industry standard. The Global Plastics Treaty negotiations, that are now on "The Road to Busan" for INC-5 at the end this year, can play an important role "...as an instrument that can drive the relevant policies and unlock financing by decreasing the risk for private capital.". Pinovo is keeping great company in the GPAP/KPMG report, as you will see from the very impressive case studies you can read about from page 19 onwards in the report below! Thank you GPAP and KPMG for choosing Pinovo as a case study, and for supporting our mission to Stop Paint Microplastic Emissions to Protect Ocean Health, because, as you know, hashtag#PaintIsPlastic! Pinovo is engaged in the UN Global Plastics Treaty process thanks to our membership of, and the excellent work being done by the WWF/Ellen MacArthur Foundation Coalition Business For A Plastics Treaty, which now comprises 220 global businesses. At Pinovo we are delighted to have played our part in the huge project on Equinor's FPSO, Johan Castberg, at Stord - see the 😳 figures below👇.

Pinovo has had a fleet of our machines on-site at Stord for the last two years, collaborating with Aker Solutions. Our technology had also been used during the construction phase of the Johan Castberg in Singapore. So, why did they use Pinovo’s Clean Blasting Technology? Thanks to a combination of industrial and sustainability advantages including 💪 You can continue to run other operations beside our equipment when it is operating, and no shut down of activity is required. 💪 There is no need for the sheeting and scaffolding that is necessary for the traditional surface treatment method of open grit blasting. 👷 Our technology is much better for operators because there is no dust or vibrations, and a lot less noise than the traditional methods. 💰 Pinovo’s solution is about 33% less expensive than the traditional surface treatment methods for spot blasting. 🌊And, of course, there are no Ocean Paint Microplastic Emissions with our dustless Clean Blasting, because don't forget #PaintIsPlastic We would like to thank Aker Solutions and Equinor for your confidence in our Clean Blasting Technology, and look forward to future opportunities to work together for better industrial and sustainability outcomes for customers, and for the Ocean 🌊. Aker SolutionsAker Solutions 🎉 𝐂𝐞𝐥𝐞𝐛𝐫𝐚𝐭𝐢𝐧𝐠 𝐚 𝐠𝐢𝐚𝐧𝐭 – 𝐬𝐨𝐨𝐧 𝐭𝐨 𝐬𝐞𝐭 𝐬𝐚𝐢𝐥𝐬 𝐟𝐨𝐫 𝐬𝐞𝐚 𝐭𝐫𝐢𝐚𝐥𝐬! 🚢 Today, over 3,000 colleagues from Aker Solutions and Equinor spent the day at our Stord yard reflecting on the incredible journey the Johan Castberg FPSO project has been – and what learnings it holds for the future. Aker Solutions has worked on the project since the early engineering phase in 2013. The floating production vessel has spent the last two years at our Stord yard for installation and final completion. Once operational in the Barents Sea, Johan Castberg will contribute significantly to European energy security. It has also safeguarded jobs and created substantial ripple effects in local communities. The project has allowed us to invest in skills development, digitalization, and continuous improvements – expertise that is transferable to other projects, including our renewables and transitional solutions. 🔹 Over 11,000 individuals have contributed to the project. 🔹 Our 1,152 subcontractors have benefitted from over NOK 3 billion in purchases. 🔹 The project has supported over 100 apprentices, reinforcing our commitment to nurturing future talent. A heartfelt thank you to all our colleagues, partners, and suppliers for their invaluable expertise and effort in making this landmark project a success! Today’s guests included our CEO Kjetel Digre, Aker ASA CEO Øyvind Eriksen, Equinor CEO Anders Opedal and Norwegian Minister of Finance Trygve Slagsvold Vedum. You really should watch the short video below 👇. It will be one minute of your time well spent! Why? Please read on! The latest round of negotiations of the proposed UN Global Plastics Treaty, INC-4, are finishing up at the moment in Ottawa, Canada. The objective is to conclude negotiations on a Treaty by the end of 2024. Pinovo was one of the early members of Business For A Plastics Treaty, a Coalition set up by World Wildlife Fund/Ellen MacArthur Foundation, that now comprises 200+ global businesses. In the Coalition we have been highlighting the importance of, and opportunity for the problem of #Microplastics in general, and #Paint Microplastics in particular, to be addressed in the proposed UN Global Plastics Treaty. Thanks to great work by Winnie Lau and Leah Mupas Segui in The Pew Charitable Trusts, and DG Environment in the EU Commission, Paint Microplastic Emissions are now firmly "on the agenda" in those Treaty negotiations. Here’s hoping 🤞 that INC-4 will keep us moving forward towards the conclusion of a UN Global Plastics Treaty. It's a once-in-a-lifetime opportunity to end plastic pollution! We call on 👉 the Paint Industry to educate its customers about the risks of mismanaged Paint, and also the solutions, 👉 Paint Users to adopt measures to stop Paint Microplastic Pollution How do you marry productivity, operator safety and sustainability in surface treatment? Well, Pinovo and Remotion AS are leading the way, and the video below 👇 shows just how we are doing it!

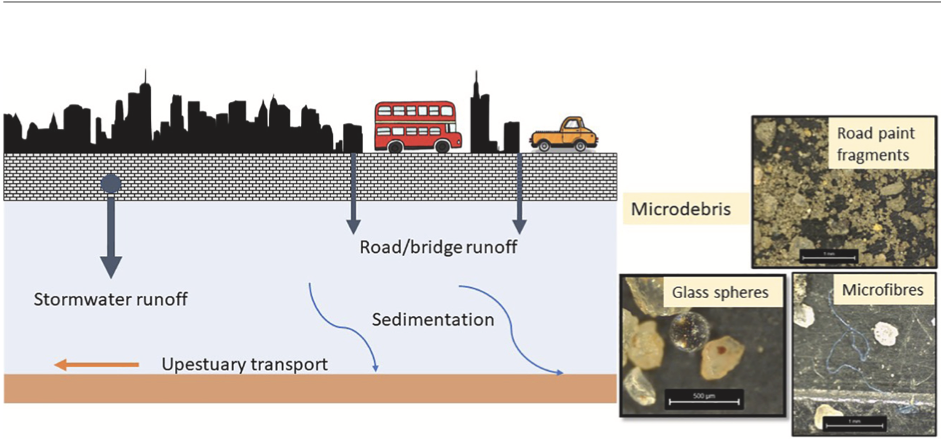

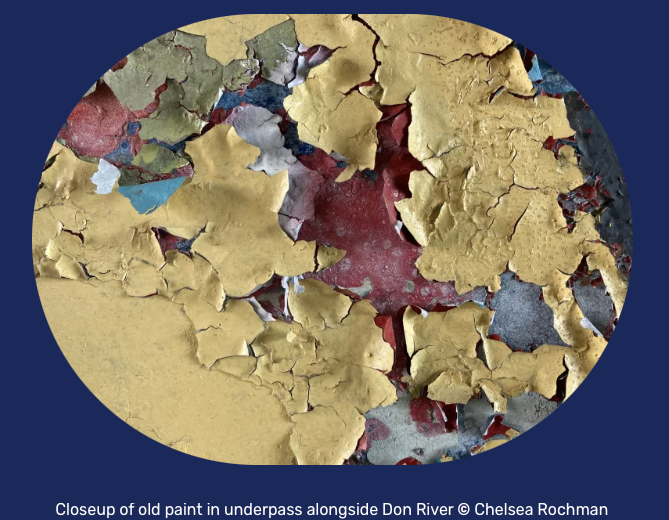

Over more than a decade, Remotion AS has been developing industry leading robotic solutions for a range of industrial activities including surface treatment i.e. removal of old paint and rust before repainting. On our side, over the same period, Pinovo has developed in-house, industry leading clean grit blasting technology that combines both industrial and sustainability advantages for customers. Both Pinovo and Remotion AS’s equipment are ATEX Zone 01 certified to enable us operate in explosive environments. Put the two technologies together, and you get solutions that are ideal for surface treatment on large flat surfaces across a range of industries, delivering cleaner, safer, and more cost efficient solutions for customers. And they stop Paint Microplastics to protect Ocean Health! Both Pinovo and Remotion AS continue to innovate to enhance our solutions - with new, higher productivity PiWalk tools from Pinovo, and new, smaller robots like the Proteus Safe from Remotion AS. So, why not talk to us to see how we can help you, and the Ocean?! 🤖 🌊 Follow this link to watch the video - https://www.linkedin.com/posts/erik-svenheim-6aa57070_proteussafe-ecofriendlytech-robotics-activity-7167176503938564096-C9aJ?utm_source=share&utm_medium=member_desktop More research has been published, and yet more is underway on both sides of the Atlantic about the importance of Paint as a source of Microplastic Pollution. Yes....more science confirming #PaintIsPlastic! First up, Dr. Andrew Turner at the University of Plymouth, who has published extensively on Microplastics, is the author of an article with Zaria West-Clarke, called "Contamination of Thames Estuary sediments by retroreflective glass microbeads, road marking paint fragments and anthropogenic microfibres". They found that "sediments of the inner Thames Estuary are known to be highly contaminated by chemical pollutants (including metals) but this study has shown that contamination extends to various forms of micro-debris”. It documents the presence (and variety) of road marking paint fragments in estuarine sediments in the marine environment (Thames Estuary). Link to research - 👉 https://lnkd.in/eURHaNzm In Canada, Zoie Diana, PhD is working in Prof. Chelsea Rochman’s Laboratory at the University of Toronto, with the U of T Trash Team to study the sources of paint microplastics in the environment, the extent of contamination of the St. Lawrence Seaway, and the ecological effects on residents animals. Check out their website 👉 https://lnkd.in/ewBpc9vZ This science based, data driven research really matters in the context of - the EU Green Deal objective of reducing Microplastic Emissions to the Environment by 30% by 2030, and - the UN Plastics Treaty negotiations, which will continue this month in at INC-4 in Ottawa, and which have include Microplastics in the definition of Plastic Pollution. Pinovo is "all in" on the use of robotic solutions in surface treatment, and delighted to be working with our Robotics Partner, Remotion AS on this project in Brazil 🇳🇴 🤖 🇧🇷 ! - see below 👇

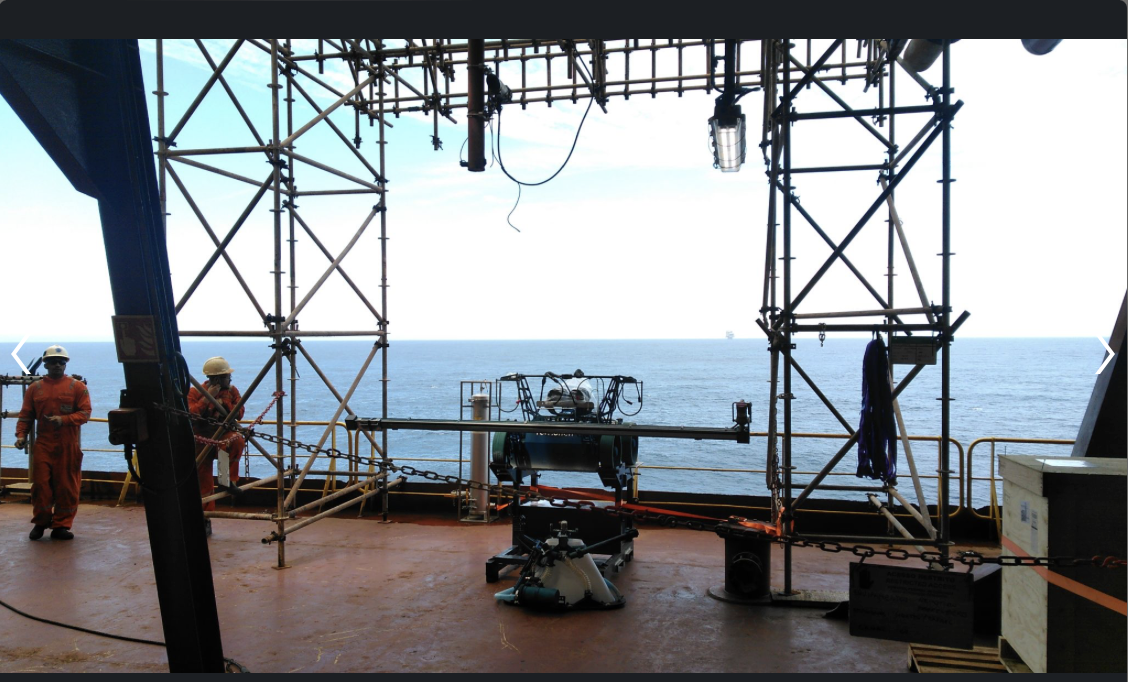

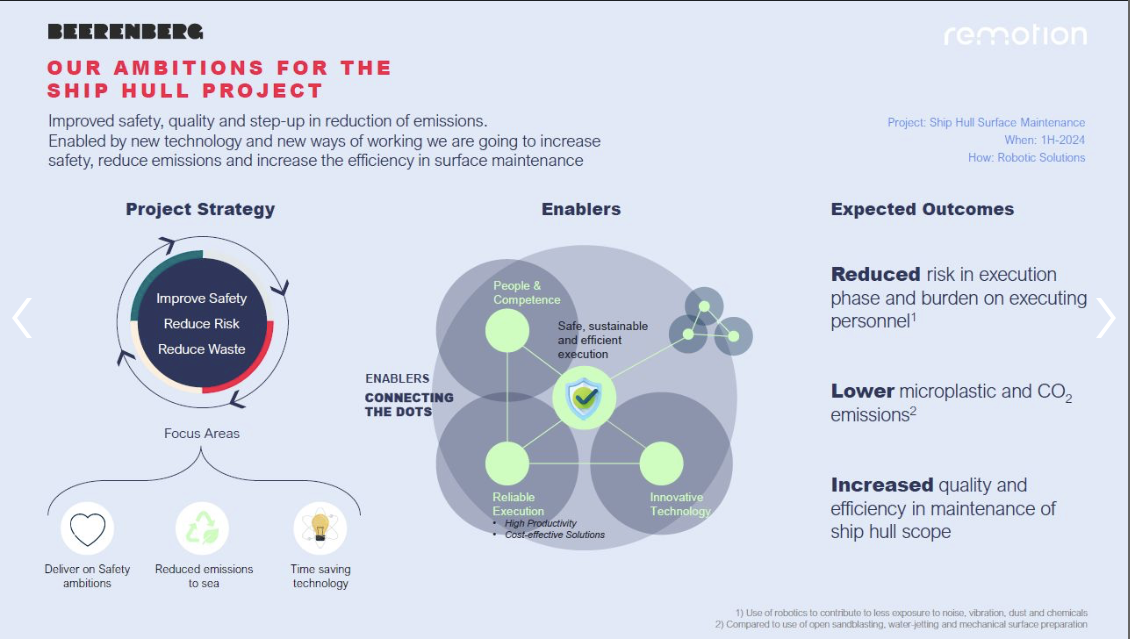

Some years ago Pinovo partnered with Remotion AS to marry our in-house developed clean grit blasting technology with Remotion AS's industry leading Robotics solutions. Robotic surface treatment solutions deliver a combination of sustainability, fabric maintenance, productivity, and health&safety advantages to customers. Both Pinovo and Remotion AS continue to invest in product development to build on those advantages. We very much look forward to working with Remotion AS's new Managing Director, Erik Svenheim, who has deep knowledge of and experience in the fabric maintenance industry, to bring sustainable robotic surface treatment solutions to more customers in more markets. Eric Svenheim General Manager, Remotion AS Exciting News Remotion and Beerenberg Undertake "World's Largest" Robotic Maintenance Project in Brazil! In collaboration, Remotion and Beerenberg have embarked on the world's largest robotic maintenance project in Brazil, revolutionizing the industry with cutting-edge technology. The project involves the pre-treatment and painting of the hull on the FPSO in operation, covering an expansive 3800 m2. This initiative sets a new standard by integrating state-of-the-art technology with a zero-emission philosophy, ensuring minimal environmental impact during the process. Not only does it represent a significant stride towards efficiency and near-zero emissions, but it also prioritizes the safety and well-being of our operators by reducing their exposure to workload and potential hazards. We extend our gratitude to the client for entrusting us with this monumental task 🤖 |

Archives

June 2024

Categories |

|

Pinovo AS, Sanddalsringen 5b, 5225 Nesttun, Norway

|