|

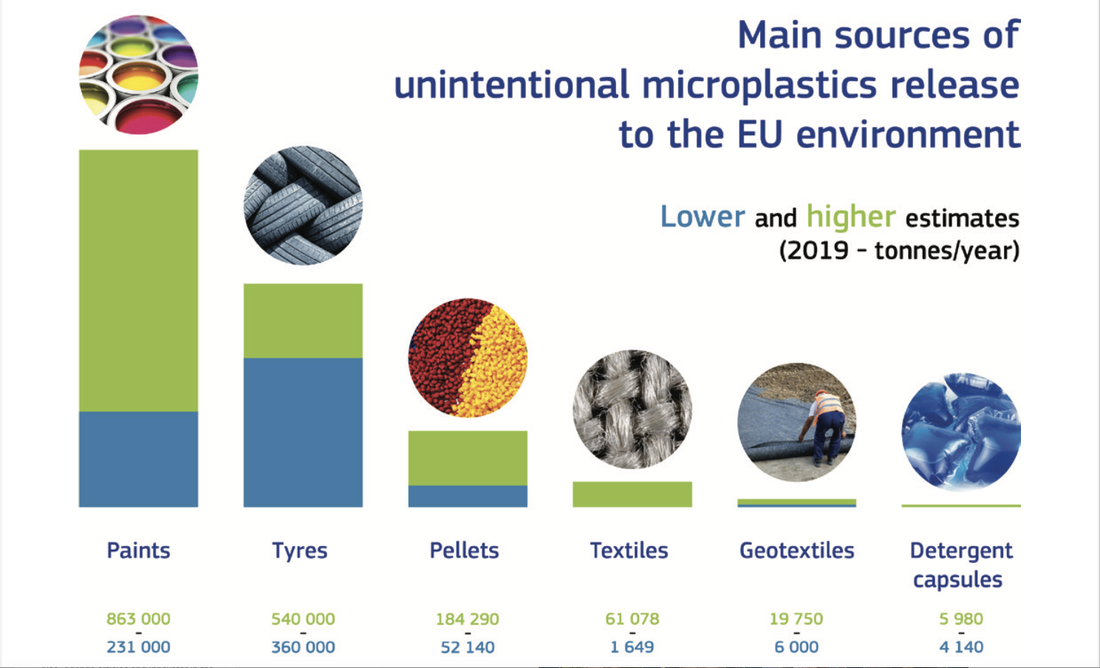

The #EUCommission has confirmed, for the first time, that #Paint is the biggest source of #Microplastics in the #Environment 😮, which for the most part end up in the #Ocean 🌊 .

The EU Commission published a brochure, "EU Action against Microplastics" last week (link to download the brochure 👉 https://lnkd.in/ewxpzCmj) after almost 3 years of intensive study and analysis. In the foreword, Virginijus Sinkevičius, European Commissioner for the Environment, Oceans and Fisheries, said ⚠ "Microplastics are accumulating in our environment" ⚠ "We now find them everywhere,…in the food we eat and the water we drink ⚠ "The risks related to high levels of human exposure are a cause for grave concern" ⚠ "The case for preventative action is crystal clear" As part of the EU Green Deal, the EU has an objective to reduce Microplastic Emissions to the Environment by 30% by 2030, and the Commission has the task of taking the necessary regulatory measures to achieve this. 💪 And what are the main sources of those Microplastics? Well, see the EU Commission’s graph below 👇 The Commission will start the ball rolling with regulations to prevent the release of Plastic Pellets to the environment. They will continue their work to identify the most effective and efficient measures to address the other important sources. On Paint, the Commission said "Relevant industries have a role in developing EU-wide guidelines to minimise microplastic releases such as on the application and removal of paints”. 👌 So, "the direction of travel" on regulation is now clear! Like the EU Commission, Pinovo calls on ✔ the Paint Industry to educate its customers on the risks of mismanaged Paint, ✔ Regulators to create a level playing field for all paint companies, ✔ Paint Users to adopt measures to stop Paint Microplastic Pollution Why? Because #PaintIsPlastic! Further scientific research on Microplastic Pollution is essential to better understand the different aspects of the problem, including the impact of Microplastics on Human, Animal and Plant Health - the all important "So what?!" question! The research work of NAMC (North Atlantic Microplastic Centre) and NORCE Norwegian Research Centre is super valuable in this regard. Pinovo will be attending the NAMC Annual Meeting in Bergen next week, and we are very excited to hear about their latest findings. #SDG14 #PaintMicroplastics #SaveOurOcean #GlobalPlasticsTreaty #Biz4PlasticsTreaty

0 Comments

Last week we started a series of Posts on our in-house developed, industry leading front end tools that are used in Pinovo's Clean Blasting technology. Next up is the PiWalk - see our short video below 👇 . The PiWalk is ideal for clean blasting of medium sized, horizontal metal surfaces, but it can also be used on vertical surfaces like the sides of tanks at the large chemical plant near Antwerp shown in the video. Hats off 🎩 to our Benelux distributor, Perspect Industrial Products and Yentl Diels! In addition to the benefits of our tools outlined below, the PiWalk also delivers productivity of up to 6 sq.m. per hour, and is super versatile across industries. It has been used on bridges (e.g. on the Flower Bridge in Trondheim), on ship’s decks (e.g. Fred. Olsen Windcarrier), and on industrial flooring. The PiWalk was also chosen by Morten Urrang's team at Remotion AS as the Clean Blasting component for RoboCoat - Remotion's robotic fabric maintenance solution that cleans, blasts and paints. This solution and Pinovo’s PiWalk was operational during summer 2023 at the Alvheim field in the North Sea on the Aker BP ASA FPSO Alvheim, and we look forward to many more mobilisations. Pinovo’s R&D is now working on a new version of the PiWalk, with higher levels of productivity, to be used with both manual and robotic solutions. 🤫 Watch this space! With the PiWalk tool, and as with all of Pinovo’s tools and equipment, 💪 There is no need for scaffolding, sheeting or shutdowns, as is the case with open grit blasting or high pressure water jetting. The Flower Bridge in Trondheim did not have to close! 💪 You can continue to run other operations beside our equipment when it is operating. 💪 Because our technology is ATEX certified, you can operate in explosive environments. 💪 With our high quality filters, and because we capture all the dust, Pinovo's equipment can also used to remove lead and other toxic paints. 💰 And, importantly, Pinovo’s solution is significantly less expensive than the traditional surface treatment methods for spot blasting, and for a continual maintenance strategy to secure life extension of painted assets. So, what are you waiting for?! Why not talk to our Operations Team in Bergen to learn more about our technology, and the benefits it can deliver for your industrial or marine business? And please don't forget, #PaintIsPlastic! #SDG14 #PaintMicroplastics #SaveOurOcean #GlobalPlasticsTreaty #Biz4PlasticsTreaty pinovo presents its industry leading front end tools for clean blasting starting with the PiConnect10/9/2023 Pinovo’s in-house R&D team has developed, over a period of a decade, an industry leading range of front end tools for our Clean Blasting Technology. As a result, we can handle the full range of work scopes and geometries, delivering both industrial and sustainability benefits for our customers. We are proud to say that they are the best vacuum blasting tools in the market, and they are tried, tested and proven! Over the coming weeks we will be presenting the full range of our tools. First out is our most versatile hand held tool: the PiConnect - see the video below👇. It is primarily intended for spot blasting and, thanks to its click-on adapter technology, a variety of surface geometries can be blast cleaned easily. The adapters handle ✅ flat surfaces, ✅ corners, ✅ edges, ✅ pipes from 3” to 10”, and ✅ even an adjustable edge for H- and T-beams! With Pinovo’s tools and equipment, 💪 There is no need for scaffolding, sheeting or shutdowns, as is the case with open grit blasting or high pressure water jetting. 💪 You can continue to run other operations beside our equipment when it is operating. 💪 Because our technology is ATEX certified, you can operate in explosive environments (it has been used inside the torpedo tube of a nuclear powered submarine, and inside nuclear power stations!). 💪 With our high quality filters, and because we capture all the dust, Pinovo's equipment can also used to remove lead and other toxic paints. 💰 And, importantly, Pinovo’s solution is significantly less expensive than the traditional surface treatment methods for spot blasting, and for a continual maintenance strategy to secure life extension of painted assets. Why not talk to our Operations Team in Bergen to learn more about our technology, and the benefits it can deliver for your industrial or marine business? And please don't forget, #PaintIsPlastic! #SDG14 #PaintMicroplastics #SaveOurOcean #GlobalPlasticsTreaty #Biz4PlasticsTreaty |

Archives

June 2024

Categories |

|

Pinovo AS, Sanddalsringen 5b, 5225 Nesttun, Norway

|