|

Next up in the profiles of Pinovo's in-house developed, industry leading front end tools for our Clean Blasting Technology is our patented PiHab™ tool - see the short video below👇 . The PiHab™, which enables clean open blasting in a confined enclosure, comes in two formats - the PiHab™ Pipe which is suitable for complex pipe or beam structures, such as flanges, supports and valves, and - the PiHab™ Flat, which can be attached with magnetic chains to any steel surface. This tool could also be described as the "missing link” of surface treatment solutions. With the PiHab™, Pinovo can undertake ALL of the workscope cleanly, including complex geometries like valves and joints, removing the need to use open grit blasting for those specific complex geometries. That is why Pinovo's customers are able to switch from the traditional “dirty” methods of surface treatment, to clean circular vacuum blasting. The PiHab™ is a unique offering in the market, and was developed by Pinovo’s R&D Department. Because we recycle and reuse the blasting grit at least 25 times, grit usage is up to 90% lower with our PiHab™ tool, compared to open grit blasting. ♻️ This means not only significant cost savings for the customer, but also over 60% lower CO2 Emissions, thanks to the lower grit usage, transport, collection and disposal. With the PiHab™ tool, and as with all of Pinovo’s tools and equipment, 💪 There is no need for the expensive scaffolding and sheeting required for the traditional surface treatment methods of open grit blasting, and high pressure water jetting. 💪 You can continue to run other operations beside our equipment when it is operating, and no shut down of activity required. 💪 Because our PiHab™ tool is ATEX certified, it can operate in explosive environments. 💪 With our high quality filters, and because we capture all the dust, Pinovo's equipment can also used to remove lead and other toxic paints. 💰 And, Pinovo’s solution is about 33% less expensive than the traditional surface treatment methods for spot blasting. This cost saving can increase to over 60% when our tools are combined with Rope Access. And finally, clean vacuum blasting facilitates a continuous maintenance strategy which gives life extension of painted steel assets, with consequent operational, financial and sustainability advantages for customers. So, what are you waiting for?! Why not talk to Pinovo's Team in Bergen to learn more about our technology, and the benefits it can deliver for your industrial or marine business? And please don't forget, #PaintIsPlastic!

0 Comments

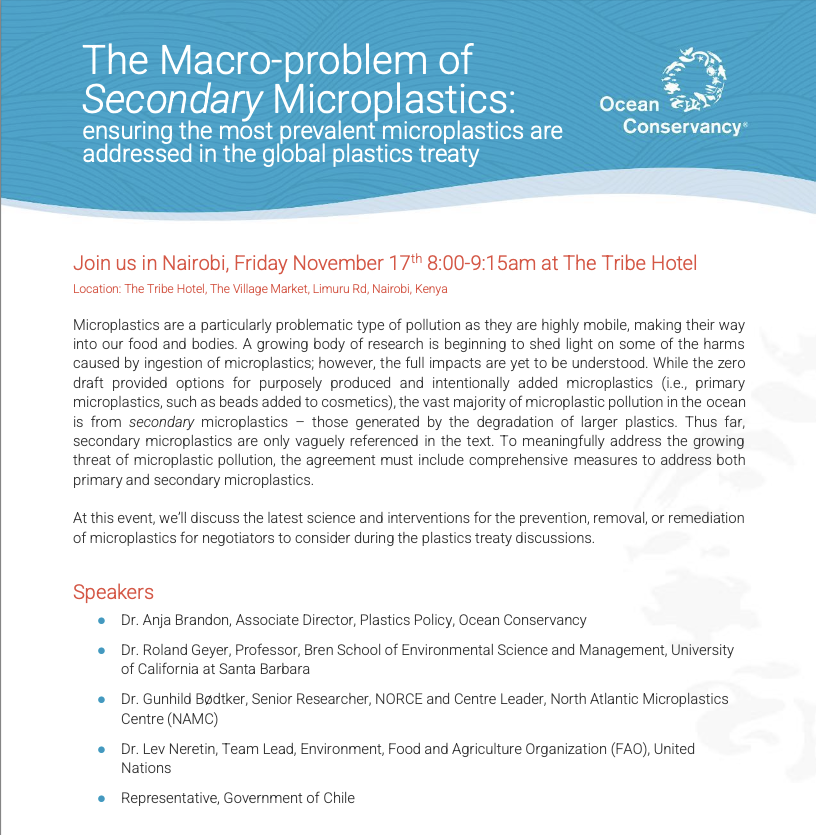

Pinovo is delighted that the problem of #Microplastics is firmly “on the Agenda” this week in Nairobi at INC-3 - the third round of negotiations of the proposed #UNPlasticsTreaty.

Quick reminder 💡 - the Resolution approving the start of negotiations of the Treaty included, for the first time, Microplastics in the definition of Plastic Pollution. Since then, thanks 🙏 to the efforts of different parties including The Pew Charitable Trusts, Ocean Conservancy and the Business For A Plastics Treaty (which Pinovo was an early member of), Microplastics have been included in the “Zero Draft” of the proposed Treaty. The issue of Intentional Microplastics (found in cosmetics, toothpaste, etc.) has been dealt with in the Zero Draft. However, the much bigger #Environmentaland #Ocean problem of Secondary (Unintentional) Microplastics i.e. Emissions from Paint, Tyres, Textiles and Pellets, needs a lot more work. Ocean Conservancy is hosting a Side Event in Nairobi tomorrow morning where experts in this area including Anja Malawi Brandon, PhD and Gunhild Bødtker from NORCE Norwegian Research Centre and Co-Leader of NAMC (North Atlantic Microplastics Centre) will highlight this issue. All of this is timely, given the recently published EU Commission brochure “EU Action against Microplastics”, confirming the scale of Microplastic Pollution, and that Paint is the primary source of Secondary Microplastics - see link to the Commission's brochure 👉 https://lnkd.in/ewxpzCmj. Pinovo is working hard to shine a light 🔦 , not only on the problem of Microplastic Emissions, but also the readily available solutions, like Pinovo's. We look forward to working with both our customers in the marine and industrial worlds, and also the paint industry (as proposed by the EU Commission). We call on 👉 the Paint Industry to educate its customers about the risks of mismanaged Paint, and also the solutions, 👉 Paint Users to adopt measures to stop Paint Microplastic Pollution Why? Because #PaintIsPlastic Continuing our series of Posts on Pinovo's in-house developed, industry leading front end tools, this week we want to tell you about our patented Pico Pipe tool - see the short video below👇 . As you see in the video, this tool has a wide range of industry applications - from the steel cables on suspension bridges, to small and large metal pipes in chemical plants, as well as across the oil&gas industry - both onshore and offshore. We have used them in Scandinavia, the Benelux, and offshore in the North Sea. The key industrial advantage of this tool is the fact that the surface treatment of pipes can be undertaken without any sheeting, scaffolding, or cleaning up afterwards, and without shutting down any operations. This patented tool can be used on a range of pipes from 2” to 8” diameter. Because we recycle and reuse the blasting grit at least 20 times, grit usage is up to 80% lower with our Pico Pipe tool, compared to open grit blasting. This means not only significant cost savings for the customer, but also over 60% lower CO2 Emissions thanks to the lower grit usage, transport, collection and disposal. With the Pico Pipe tool, and as with all of Pinovo’s tools and equipment, 💪 There is no need for expensive scaffolding and sheeting, which is required with the traditional surface treatment methods of open grit blasting, and high pressure water jetting. 💪 You can continue to run other operations beside our equipment when it is operating, and no shut down of activity required. 💪 Because our technology is ATEX certified, you can operate in explosive environments. 💪 With our high quality filters, and because we capture all the dust, Pinovo's equipment can also used to remove lead and other toxic paints. 💰 And, Pinovo’s solution is about 33% less expensive than the traditional surface treatment methods for spot blasting. This cost saving can increase to over 60% when our tools are used with Rope Access. And finally, clean vacuum blasting facilitates a continuous maintenance strategy which delivers life extension of painted steel assets, with consequent operational, financial and sustainability advantages for customers. So, what are you waiting for?! Why not talk to our Operations Team in Bergen to learn more about our technology, and the benefits it can deliver for your industrial or marine business? And please don't forget, #PaintIsPlastic! |

Archives

June 2024

Categories |

|

Pinovo AS, Sanddalsringen 5b, 5225 Nesttun, Norway

|