“Including all activities, from scaffolding to sheeting, blasting, cleaning and painting, the use of PiHabs has increased our overall efficiency by 100%. It's also better for the operators from a health and safety perspective”

- GER VAN HEESCH, supervisor protective coatings at PCC / Verwater Group B.V.

Dustfree vacuum blasting systems- ATEX certified (zone 1)

- No clean-up or sheeting - Typically 75% reduced waste - No damage to surrounding equipment - Perfect for spot repairs, welding seams, flanges and rope access |

|

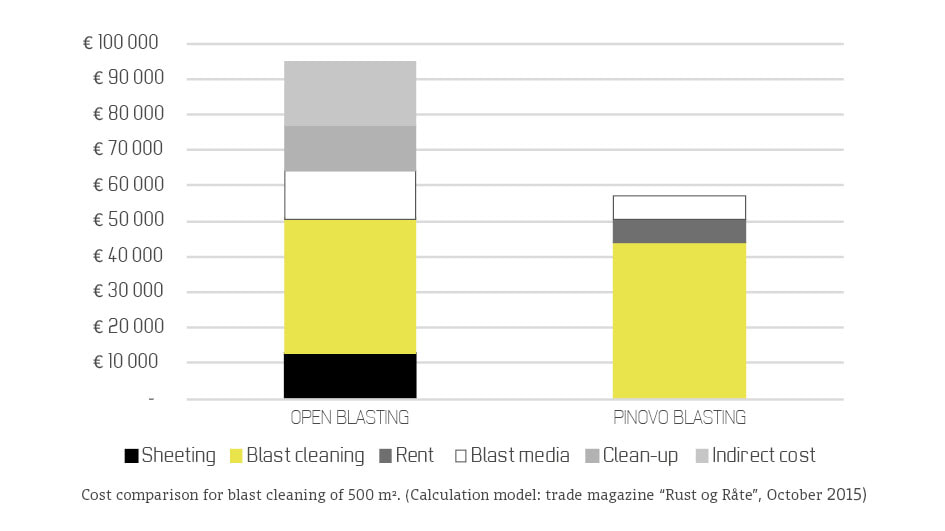

COST reduction

|

Our customers reduce their project costs significantly due to high quality spot blasting, no dust or spill and safe execution.

COST-REDUCING PINOVO FEATURES: - No flying grit or dust reduces, and often eliminates, the need for barriers, scaffolding, sheeting and clean-up - Extended lifespan on spot repairs (same as open blasting, 15-20 years) - Other work disciplines are not affected and can work side by side with PINOVO® enclosed blasting tools - Recycling the blast media gives significantly reduced blast media consumption and typically 75% reduced waste -No damage to surrounding equipment -Low noise and no vibration on the tools means no work restrictions for time on tool and less personnel needed |

SUPERIOR SURFACE QUALITY

|

Pinovo vacuum blasting provides a clean operation with the same surface purity and roughness as open blasting. This ensures a permanent repair with the same lifespan as the original coating.

DO IT PROPERLY, DO IT ONCE: - The PINOVO® tools leave a clean and dry surface (Sa 2½-3, from sweep blast to 120 µm), ready to be coated immediately after blasting - Feathered edges ensures a perfect transition between old and new coating system when blasting spots - Even suitable for metallization |

|