|

BlueInvest Day in Brussels on 7th March was a great opportunity to tell a new audience that #PaintIsPlastic, Paint is the biggest source of Microplastic Emissions, and there are proven, effective solutions like Pinovo's clean blasting technology.

Hats off to EUCommission and PwC for their excellent organisation of the event.

0 Comments

Pinovo was delighted with the recent article about its business and financial results in the respected Norwegian financial newspaper, Finansavisen.

The article (behind a paywall, sorry 🤷♂️ !) highlights the positive impact that Pinovo’s focus on customer service and sustainability has had on its financial performance. Joakim Olausson, General Manager of Pinovo, explained in an interview that our sustainability focus resonates well with the “Green Shift” which Pinovo is seeing in industries like Oil&Gas, Infrastructure, Defence and Shipyards. Thanks to a combination of industrial traction, and the increasing regulatory tailwinds pushing for clean solutions, Pinovo is scaling up its operations to meet growing customer demand. Yet more research has been published recently by leading scientists confirming the prevalence of Microplastics in general, and Paint Microplastics in particular.

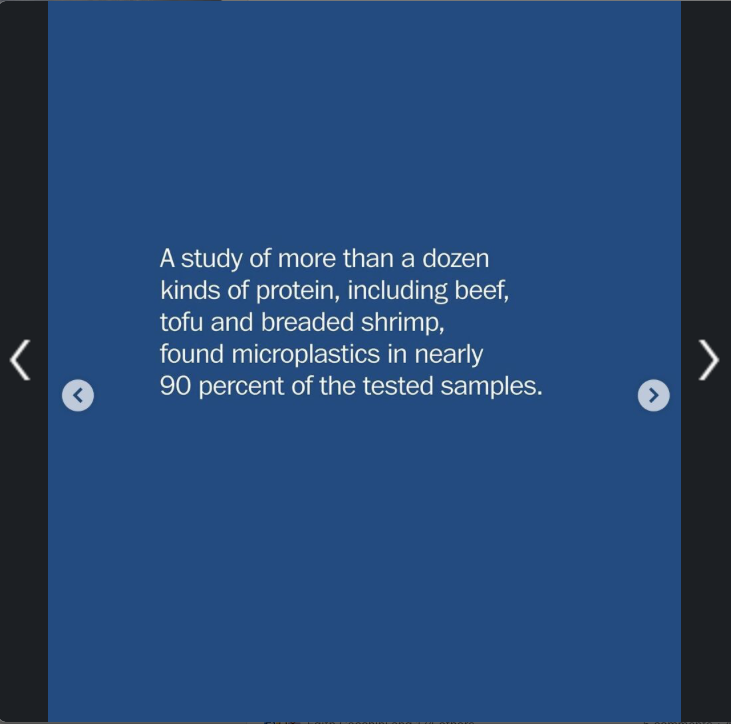

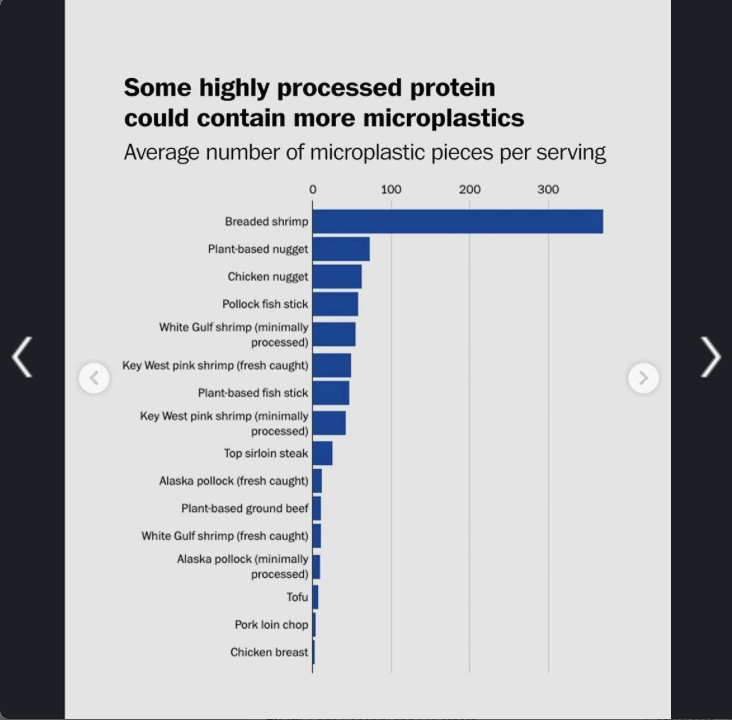

First up, Professor Chelsea Rochman and her team at University of Toronto (U of T Trash Team) worked with Ocean Conservancy, including their Microplastics expert, Britta Baechler, Ph.D., to test samples of different proteins we consume for the presence of Microplastics. The big finding is that "It's not just Seafood" that contain Microplastics! 😲 They were found in all 16 types of proteins tested, including meat, and even plant based proteins. This suggests that humans are most likely eating microplastics no matter the source of protein they choose. 🤷♂️ Follow this link to the Ocean Conservancy article on the research 👉 https://lnkd.in/gqmTXSNp This is why the work of the EU Commission to tackle the big problem of Microplastic Emissions to the Environment, and the upcoming INC-4 talks in Canada in April on a Global Plastics Treaty really do matter. Pinovo is honoured and super excited to have been chosen as one of the Finalists to pitch our solution at the #BlueInvest Day on 7th March in Brussels.

#BlueInvest Day has been organised by the #EuropeanCommission each year since 2018, to bring together entrepreneurs and investors committed to fostering innovation and sustainability in the EU Blue Economy. Pinovo will be in great company, pitching alongside our friends Finsulate BV, who are also fighting paint microplastic pollution, as well as Hefring Marine, ICODOS, and PRONOE. You should check out all of their impressive solutions! This will be a great opportunity for Pinovo to tell a new audience about the problem of Ocean Paint Microplastic Pollution, and Pinovo's solution, and of course, to remind everyone there that #PaintIsPlastic! One of the objectives of the EU #GreenDeal is to reduce Microplastic Emissions to the Environment by 30% by 2030. Last October, the #EuropeanCommission published a brochure confirming that #Paint is in fact the biggest source of those #Microplastic Emissions. Pinovo's solution is playing its part in helping achieve the #GreenDeal objective. Go to this LinkedIn Page to see the EU Commission Post 👉 https://www.linkedin.com/posts/eu-business-showcase_blueinvest-begreengoblue-smes-activity-7164260226144137217-Up_m?utm_source=share&utm_medium=member_desktop At Pinovo we wanted to tell you about three particular moments from the recent #WEF24 in #Davos that marked us, and that we think might interest you too!

Firstly, watching Dr. Diva Amon being interviewed live in a submersible 350m below the surface of the Ocean 😲, and explaining why the research being undertaken on OceanX, really matters! Go to 35 mins 30 sec on the link 👉 https://lnkd.in/eKfbwVF8 to watch the interview. Secondly, Professor Douglas McCauley did a great job moderating an impressive panel that spoke about why landing the #UN #PlasticsTreaty is so important. Minister Leila Benali, PhD., President of UN Environment Assembly, “nailed” it when highlighting the scale of under researched Microplastic Pollution, and why the proposed Treaty should tackle it now for human health reasons! Go to 6 mins and 30 sec on 👉 https://lnkd.in/eYdF5Jt8 to hear the Minister talk about the issue. This is something very close to our hearts at Pinovo, given our technology stops Paint Microplastic Emissions - the biggest source of Microplastic Emissions into the Environment, according to the researchers at EA - Earth Action, The Pew Charitable Trusts and the #EUCommission. Finally, the #HighSeas (#BBNJ) Treaty, signed in 2023, was the subject of a panel discussion where they spoke about the business and government implications of this Treaty. Ambassador Peter Thomson, the UN Special Envoy for the Ocean, reminded us of the need to focus on SDG 14 and Ocean Protection, or as he puts it so well, "No Healthy Planet without a Healthy Ocean". Go to 40 mins and 45 sec on the link 👉 https://lnkd.in/eRQgGRVe to listen to Ambassador Thomson. These issues guide and drive us at Pinovo in our work to Stop Paint Microplastics to Protect Ocean Health, because #PaintIsPlastic After a great year in 2023 on both the sustainability and operational fronts, we are glad to say that 2024 has started with some fantastic news for Pinovo!

In 2023, thanks to the industrial adoption of our technology, Pinovo saw its growing machine park fully rented out again to customers who get both the industrial and operational benefits, and also the sustainability advantages of using our technology. In addition, in 2023 #Paint was confirmed as the primary source of #Microplastic #Emissions to the #Environment by both The Pew Charitable Trusts and the #EUCommission, with the Commission saying that “...Relevant industries have a role in developing EU-wide guidelines to minimise microplastic releases such as on the application and removal of paints…”. Pinovo has developed, patented and proven technology that does just that! Very happy and proud to say that we start 2024 with news of not just one, but two nominations of Pinovo’s solution for The Earthshot Prize!! To paraphrase a certain Danish brewer, The Earthshot Prize is "Probably the Best Environmental Impact Prize in the World", and it is a really great honour for Pinovo to have been nominated for it! We like to see these nominations as further recognition of the importance of the problem of Paint Microplastic Pollution, and support for Pinovo's mission and solution to Stop Paint Microplastics to Protect Ocean Health! Because, #PaintIsPlastic! A big thank you 🙏 to everyone - our employees, customers, distributors, suppliers, and all of the great, great supporters of our mission - who contributed to making 2023 the best year ever for Pinovo, for both Ocean Impact 🌊 and Operations 🏭 ! Onwards and upwards! 🚀 Pinovo's Clean Blasting - Stops Paint Microplastics to Protect Ocean Health Because #PaintIsPlastic! Pinovo "on tour" again! As a result of having won the Special Prize for Marine Biodiversity Solutions from the French government agency, Office français de la biodiversité (OFB) at the 2023 Ocean Pitch Challenge - organised by RespectOcean and Sustainable Ocean Alliance.

As part of this Special Prize, Alain PIBOT of OFB kindly invited Pinovo to attend Les Assises de l'économie de la mer (AEM) in Nantes, and to be part of the OFB stand. AEM brought together 1,800 participants from all parts of the French Maritime industry - from the French Navy, through shipbuilders, port operators, logistics companies, aquaculture companies, researchers, regulators, bankers, innovators, etc., etc. This was a great opportunity for Pinovo to raise the issue of Ocean Paint Microplastic Pollution, and our solution to this important Ocean problem, with the French maritime industry, and also in front of some very senior French politicians - see photo below! A key theme throughout the two days of presentations was sustainability, and the importance of Ocean Protection. Pinovo’s mission to stop Paint Microplastics to Protect Ocean Health found a ready and interested audience! Thank you once again to Olivier Thibault, directeur général de l’OFB, and his colleagues, Alain PIBOT, Laetitia Miquerol, and Aurélien VIAU for their support and encouragement for Pinovo’s mission to protect Ocean Biodiversity and Health. It was particularly interesting to meet the French Navy (Marine Nationale) and NAVAL GROUP, and to discuss the potential for them to use Pinovo’s clean surface treatment method, as it is currently being used by the Forsvaret - Norwegian Armed Forces (Navy), Royal Navy in the UK, and Swedish Armed Forces (Navy). Pinovo has been “on tour” in recent weeks bringing our message of #CleanBlasting to both customers and the sustainability community across Europe.

First up, Pinovo attended the Offshore Energy Exhibition & Conference 2023 (OEEC) in Amsterdam last week. This annual event brings together the international #OffshoreEnergy community - producers, contractors, suppliers, thought leaders, industry experts - who operate with #OffshoreWind, #oilandgas , marine energy, hydrogen sector, etc. Pinovo’s Benelux distributor, Perspect Industrial Products organised a stand at the OEEC2023 with Pinovo and Safety Tools Allmet AS. The common denominator is #ATEX - a key safety feature of Pinovo’s and Allmet’s equipment, which means our equipment can be operated safely in explosive environments. This matters! We operate our technology on board working oil rigs, and in operating chemical plants, without the need for shutdowns. A big focus at OEEC this year was on wind energy. Pinovo is currently developing a bespoke clean surface treatment solution for offshore wind turbines. We are doing this with the support of Handelens Miljøfond, and in partnership and consultation with experienced wind energy industry players, including KONGSTEIN, Hafslund Eco and Ørsted. It was great to meet our customers and talk about their plans for 2024 and beyond, and also to discuss opportunities to work together in other industries and geographies. Important to see the awareness of both the industrial and sustainability advantages of, and the necessity for Clean Surface Treatment Solutions in the Offshore Energy community. And also great to see their awareness that #PaintIsPlastic! Great to get a shout out for Pinovo, as one of UpLink - World Economic Forum Top Innovators from John Dutton, Head of UpLink! See the Post and video below 👇

Pinovo is in truly amazing and inspiring company when you see the other UpLink Top Innovators! 😲 UpLink - World Economic Forum has helped raise awareness that #PaintIsPlastic.....bigly! 💪 Thanks to the World Economic Forum Digital Team! 🙇🏻 Hats off to Ross Chainey, Emanuela Orsini, Kaya Bulbul and the rest of the Team! 🫡 John Dutton• Head of UpLink at World Economic ForumHead of UpLink at World Economic Forum Followers of UpLink - World Economic Forum will hear us talk a lot about our our community of 'Top Innovators' - the early-stage, purpose-driven entrepreneurs with scalable ventures who are working tirelessly to solve a host of environmental, societal and economic challenges. But what exactly is an UpLink Top Innovator? What types of solutions are they working on? What problems are they solving? What impact are they having, and what impact is UpLink having on them? To answer these questions, our incredible digi team made this video featuring just a selection of the amazing entrepreneurs who inspire us every day. Don't take it from us, take it from this inspiring group of entrepreneurs we've been blessed to support... Follow this link to see the video - https://www.linkedin.com/posts/activity-7136371398364536833-UdRr?utm_source=share&utm_medium=member_desktop |

Archives

June 2024

Categories |

|

Pinovo AS, Sanddalsringen 5b, 5225 Nesttun, Norway

|