|

After #sustainability, the other big macro trend in surface treatment is #robotics, and here again, Pinovo is "all in"!

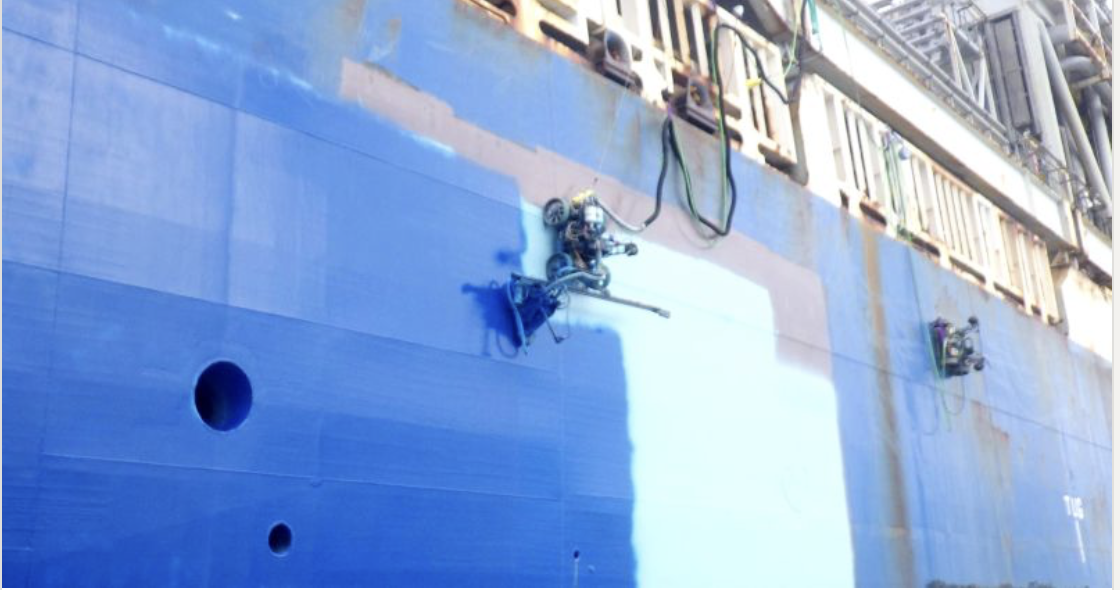

Robotics increase the productivity of clean vacuum blasting, making it suitable for use on large flat surfaces such as ships’ and FPSOs' hulls. Pinovo was delighted that its Clean Blasting Technology was chosen by Remotion AS for the surface treatment piece of Remotion's Robocoat solution, providing high quality surface roughness before re-coating. See below a photo and report from Remotion AS on work currently underway on an Aker BP ASA FPSO, using Remotion AS's robotic solutions, and Pinovo's clean blasting technology. We look forward to collaborating with Remotion AS at other customers's sites in Scandinavia, and across Europe, and in other industries such as at chemical plants with large tanks that are suitable for robotic solutions, but need a high quality surface finish prior to re-coating, as provided by Pinovo. Pinovo's technology is also a clean sustainable solution, stopping Paint Microplastic Emissions, and ideal for spot blasting! Because, let's not forget, #PaintIsPlastic! 🎨 Here is a picture from one of our ongoing operations this summer where we are offshore doing a complete hull surface campaign on an FPSO. The robots have degreased the surface, removed all old paint, grit blasted the surface to Sa 2.5, feathered edges and are now applying a high-quality three layer coating system according to NORSOK M-501 standard. ♻ All preparation sequences are done with collection of the waste. Coating is carried out with our unique airless spray paint shielding hood that significant increases transfer efficiency of paint and thus prevent overspray being released to the environment. 🚀 In general the robotic solutions work more efficient and safer on vertical hull areas, but it gets even better when we use more of them! On this project up to three robots are in operation. On the picture one Helios robots is painting, a other is idle on the hull waiting to start surface preparation, while a third robot is standby for hot water high pressure water cleaning before each coating sequence. All robots are operated beyond line of sight with its topside spread according to ATEX Zone 02 and NORSOK Z-015 regulations. 🌦 When offshore campaigns last for months, the diversity of weather is significant. Tools like the spray paint shielding hood increases the operational wind restrictions, but in addition our skilled personnel plan according to weather forecast so that for example surface preparation that can be done in rain and windy conditions is completed before the good weather painting days, with the result that the operation progress almost regardless of the weather.

0 Comments

Leave a Reply. |

Archives

June 2024

Categories |

|

Pinovo AS, Sanddalsringen 5b, 5225 Nesttun, Norway

|