“Including all activities, from scaffolding to sheeting, blasting, cleaning and painting, the use of PiHabs has increased our overall efficiency by 100%. It's also better for the operators from a health and safety perspective”

- GER VAN HEESCH, supervisor protective coatings at PCC / Verwater Group B.V.

Dustfree vacuum blasting systems- ATEX certified (zone 1)

- No clean-up or sheeting - Typically 75% reduced waste - No damage to surrounding equipment - Perfect for spot repairs, welding seams, flanges and rope access |

|

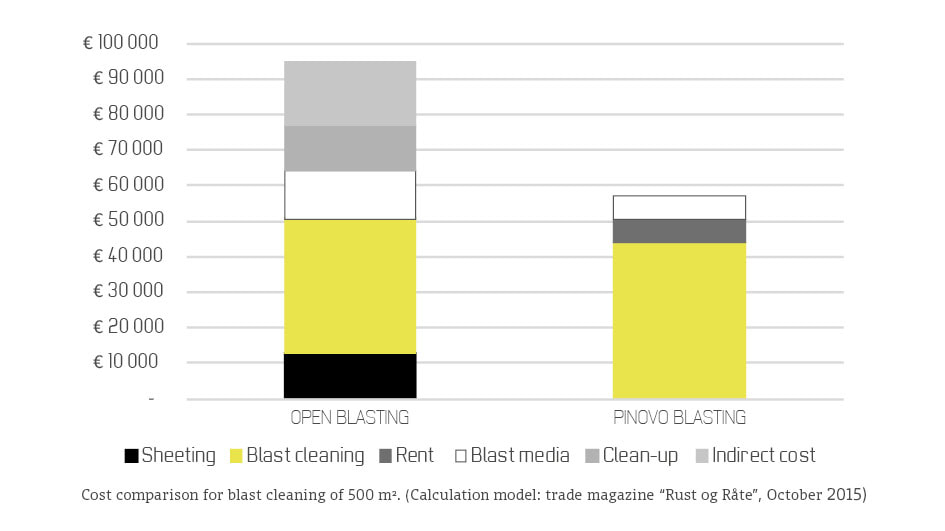

COST reduction

|

Our customers reduce their project costs significantly due to high quality spot blasting, no dust or spill and safe execution.

COST-REDUCING PINOVO FEATURES: - No flying grit or dust reduces, and often eliminates, the need for barriers, scaffolding, sheeting and clean-up - Extended lifespan on spot repairs (same as open blasting, 15-20 years) - Other work disciplines are not affected and can work side by side with PINOVO® enclosed blasting tools - Recycling the blast media gives significantly reduced blast media consumption and typically 75% reduced waste -No damage to surrounding equipment -Low noise and no vibration on the tools means no work restrictions for time on tool and less personnel needed |

IMPROVEd HSE

|

Use of Pinovo equipment reduces the risk of eye injuries, hand-arm vibration syndrome and hearing loss among surface treatment operators. The technology also eliminates the risk of pollution to the air and surroundings, which means that other work disciplines can continue their work side by side to the Pinovo blasting.

LOW NOISE, NO DUST AND NO VIBRATION: - No pollution of nearby environment - Low noise reduces the risk of hearing impairment - No flying grit or dust reduces the risk of eye injuries - Optional use of HEPA-filters for blasting on hazardous coating/material - No vibrations in tools eliminates the risk of hand-arm vibration syndrome - Lesser and more comfortable personal protective equipment - ATEX certified and can be used in explosive areas - Integrated waste management system - Low weight and ergonomic design - Reduced carbon footprint - No gas emissions |

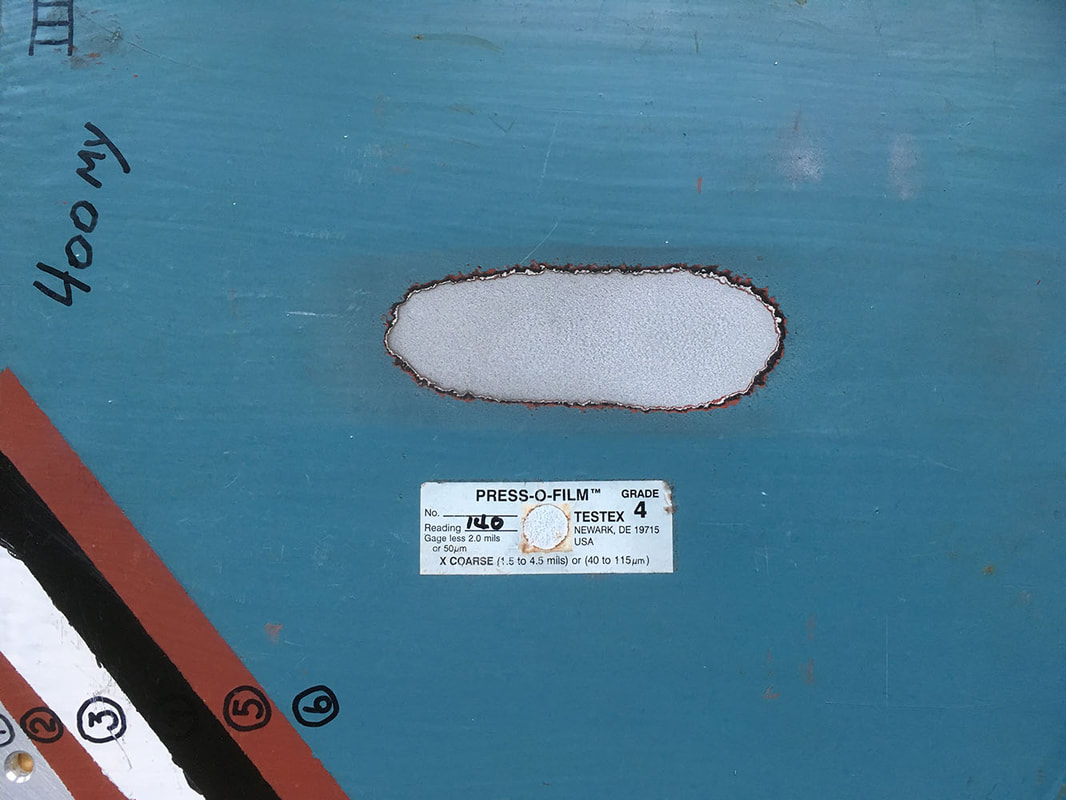

SUPERIOR SURFACE QUALITY

|

Pinovo vacuum blasting provides a clean operation with the same surface purity and roughness as open blasting. This ensures a permanent repair with the same lifespan as the original coating.

DO IT PROPERLY, DO IT ONCE: - The PINOVO® tools leave a clean and dry surface (Sa 2½-3, from sweep blast to 120 µm), ready to be coated immediately after blasting - Feathered edges ensures a perfect transition between old and new coating system when blasting spots - Even suitable for metallization |

|